There are some dream projects for a lot of new welders that they have been looking forward to work on ever since they started welding. Welding a truck or a car frame is one of those for a lot of people. if you don’t know a lot about this topic this might seem like a very simple thing to do if you know how to perform basic welds. But the reality is a little different. In this article, I will try to address all the factors related to welding a truck or a car frame.

The legality of welding frames of trucks can differ from one state to another but at the federal level, you have to strictly adhere to the manufacturer’s guidelines otherwise the vehicle will not be highway legal.

It is important for you to know the different ways you can look for frame defects in your car. You also have to be extra careful when it comes to the safety aspect of welding truck or car frames as a lot of times, any repair work compromises its safety.

IS IT LEGAL TO WELD TRUCK FRAMES

Contents

Before I get into these topics, it goes without saying that you should consult a legal professional about this topic to get to know everything in detail. I am going to try my best to explain the legality of the situation but it might not be an accurate representation of the law.

It is not strictly illegal for you to weld your truck frame. According to the law, it has to strictly adhere to the manufacturer’s guidelines. This is what is stated at the federal level but may be different at the state or the local level. I will state again that if you have plans to weld on your truck or commercial vehicles, consult an attorney before you do it.

As I said before if you have decided to go ahead with welding your truck frame, be very careful about reading preparation procedure, equipment, and the best methods for going about it.

IS IT OKAY FOR YOU TO DRIVE A COMMERCIAL VEHICLE WITH WELDED FRAME ON THE HIGHWAY?

Any commercial vehicle which includes a bus, large truck, or an 18-wheeler can only be operated on the highway with a welded frame if it strictly adheres to the manufacturer’s guidelines. If you are going to do the weld on your own, the probability of your vehicle adhering to the strict guidelines is going to be very low. This law has been stated under the Federal Motor Carrier Safety Administration Title 49: Subtitle B: Chapter III: Subchapter B: Part 393.201 (d).

These guidelines are usually pretty strictly enforced and for a moment it might seem like overkill but all of this is done for safety purposes. It goes without saying that large vehicles or any vehicle for that matter poses a safety risk not just for the people inside the car but to the surroundings as well. and you don’t want a structurally weak 18-wheeler crashing into anything.

A similar law which might be a common ground for commercial vehicles and heavy consumer vehicles makes it illegal for you to drill holes on the bottom or top rail flanges, of course, unless it is within the guidelines provided by the manufacturer. I am not completely certain about this but if your frame rails have been modified in any way like being cut or drilled, the vehicles might not be highway legal anymore.

One way to get around modifying your vehicles is to get them registered as “off-highway” only, this way the restrictions become much more relaxed. (don’t take this as legal advice on the matter and consult a legal professional)

WHAT HAPPENS IF YOU ARE CAUGHT DRIVING SUCH A VEHICLE ON THE HIGHWAY?

If you are driving or operating a vehicle on the highway which shouldn’t be there because of having a welded frame or if it does not fulfill any one of the legal requirements, you and your vehicle can be sent to the State Vehicle Referee. The SVR will examine your vehicle and look for anything which might not meet the legal requirements and this can lead you to getting heavy fines.

CAN YOU SELL A VEHICLE WITH WELDED FRAME?

The details of the law can be different for different states and jurisdictions but at its most basic, it is not illegal for you to sell a modified vehicle as long as you clearly mention the changes which have been made to the vehicle before or at the time of the sale.

The reason for this becomes clear when you start thinking about the safety reasons associated with it. If you make some changes to the frame of your truck and decide to sell the truck to someone, its safety might have been compromised and it is important for the other person to be made aware of any changes made to the vehicle.

OTHER LEGAL ISSUES

Another important reason to make everything clear at the time of sale of a vehicle with a welded frame or even if you have done a repair job for someone are the added liability reasons. If the vehicle you have made changes to gets into an accident, you could be held liable for any changes you made which might have affected its safety.

Another factor is the insurance policy issues. You might not be able to claim your insurance policy on your vehicle if the company finds out you made any changes that violated their insurance clause. (consult an attorney for any legal advice)

COMMON PROBLEMS WITH TRUCK FRAMES

There are some issues with truck frames which are common all over the globe and over every manufacturer. These problems can be caused by overtime or through some collision or other sources of damage. Some of these causes include poor build quality, fatigue, stress and can be a combination of any of these things.

One of the most common problems which people face with truck frames is bending. Bent frames are very common in car accidents but can be caused by other factors too. One of these factors is static overload which basically means too much cargo impact or maybe by dropping something onto the cargo body. Bending can result in a permanent change in the shape of the frame or can be minor deformations that you might not even notice at first.

Another issue that can arise is cracking. It can be caused by poor build quality or fatigue and high-stress level build-up over time. If the crack occurs between the axles, it can begin from the bottom flange but move upwards through the web.

HOW TO CHECK FOR FRAME DAMAGE ON A CAR

You might be surprised to find out that your vehicle frame has been compromised as not all issues can be easily noticed especially by people who are not specifically looking for them. as you know a frame of the vehicle determines its structural integrity and any problems with it should be swiftly dealt with. There are some ways you can check if your vehicle frame has been compromised.

CHECKING FOR VISIBLE DAMAGE

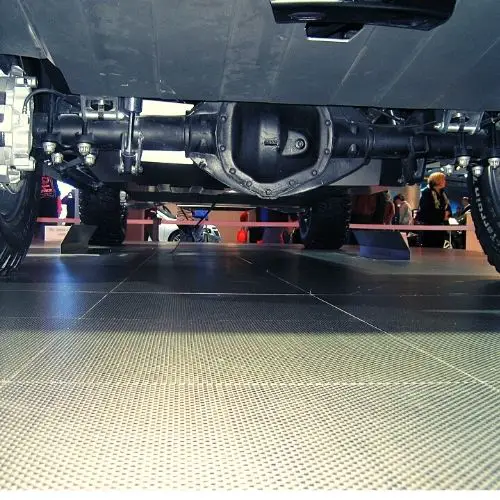

One of the most common ways for checking any defects in your vehicle is to take a direct look at the frame by crawling under it. With a simple flashlight, you can easily check for any damage. Some parts of the frame are visible under the chassis which can be used to check for any bend or any cracks by using a simple flashlight. You should specifically check for these issues if you are in the market for buying a used car.

FITTING ISSUES

For people who are not aware of frame issues that can arise, checking the fitting of different vehicle components might be a good place to start looking for problems. One of the most common places to look for them are the doors. If your car doors are not closing properly and there doesn’t seem to be an obvious issue with the latches then frame bending might be one of the issues.

Bending of frames can also be noticed if your car panels are bent inwards or outwards or can be bent by slight pressure on the panel. This can be formed because of gaps between body panels arising due to a bent frame.

CHECK YOUR SHOCK AND SUSPENSION

The frame of a vehicle also does the job of distributing weight evenly on all sides of a car. If the frame is damaged it may result in the load being unevenly distributed between the suspension. If your shocks or suspension is being worn away relatively faster in one side you might want to get your frame checked.

VEHICLE WEERING OFF

If you have noticed that your vehicle keeps moving to one side even if you are not touching the steering wheel then a frame issue might be behind it. Vehicles with bent frames have a hard time maintaining proper alignment.

IS IT LEGAL TO WELD YOUR CAR FRAME

The laws surrounding the legality of welding car frames differ slightly when it comes to commercial vehicles and consumer vehicles like cars. Although a lot of people don’t recommend you making repairs on your car frames by yourself because of safety reasons.

The answer to whether it is legal for you to weld your personal vehicle’s frame is yes. You can weld the frame but make sure it is according to the manufacturer’s guidelines. (please take proper legal advice from a professional attorney). The laws may be different for different states.

DOES WELDING A SUBFRAME WEAKEN IT

As it comes with a lot of topics related to welding, there is no clear-cut right answer. Some people claim that welding a subframe does not weaken if done properly. But I am guessing the people with the required expertise to correctly do the job already are professionals.

When it comes to normal people like you and me, performing a good weld on a subframe will probably not result in a good weld. subframes come under the category of highly stressed components, any repairs or welds on it might mean that the original structure has lost some of its integrity.

If there is corrosion on the subframe and it has reduced its thickness or caused some holes or splits then performing a weld on it might result in a less safe vehicle for you to drive. This is because it being such a highly stressed component. You should seek some professional help in dealing with your subframe.

WHAT TYPE OF WELDING IS USED FOR CAR FRAMES/CHASSIS REPAIR

As usual, there is a division among the community over which method is the best. There is a general division among the people over two methods, MIG or TIG. Probably the answer depends on preference and such but most of the people I have talked to prefer one over the other and for reasons which I agree with.

I would advise you to use MIG over TIG when you are welding truck frames. For one, MIG is considered to be easier to use over TIG, and on top of this, it is easier to correct as well. it is also considered better for the bigger weld. TIG on the other hand works better on thinner metals. The fact that MIG is easier to use and easier to correct as well makes sense why it is preferred by a lot of people.

TIG welding can be the preferred choice if you are dealing with frames that have chrome-moly tubing or if the frame contains curvatures, for example, if you are dealing with racing cars. TIG is also preferred when dealing with high alloy steels which are heat sensitive.

IS WELDED CAR FRAME SAFE

The reason for the strict laws surrounding the legality of welding truck, and car frames largely involve its safety aspect. Some people claim that welded car frames can retain the original level of structural integrity. I don’t think so, an average welder performing a weld on a car frame will not be able to do a good enough job with it.

As I have stated earlier, a vehicle’s frame does a lot of jobs like maintaining the car’s balance, structural integrity, and overall safety. So it is obvious that any changes made to such an important part of the vehicle can have a huge impact on the overall safety. You should be very careful when selecting the professional to get the job done. In a nutshell, a welded car frame can be safe but the margin of error is pretty huge and can have very big consequences.

HOW DO YOU WELD AND CUT A TRUCK FRAME

If you have decided to go for welding the truck or the car frame on your own, there are a few things that you should keep in mind before attempting the weld.

The first step is to make sure that the frame is clean and free of any rust, paint, grease. Once you have made sure of that, the next step would be to ensure that the frame is level and straight. Professionals have the tools at their disposal to make sure all of these steps are properly taken care of.

Once you have made sure that the frame is level and straight, you want it to remain like that when you are working. For this, you should mount the frame on jack stands to secure it. Once you have taken care of these basic steps you can go ahead with starting your weld.

When you are about to start your weld, make sure that you have studied the manufacturer’s guidelines and you have a plan on how to go about the whole process.

Some of the basic things that a lot of people forget are to match the yield strength of steels as closely as possible. Have some margin of error so that the frame will be able to support the heavy payload. Also, don’t skimp on the materials when it comes to this project, remember that more steel is stronger than less steel. Also, make sure that you are tapering and staggering your reinforcements which will help you to distribute the repair over a larger area. Sudden changes in the constitution of the frame can lead to weaknesses.

CHALLENGES WHICH CAN ARISE WHEN WELDING TRUCK FRAMES

For a lot of novice welders, fixing a dent or a crack on a frame might seem like a straightforward thing to do. But in reality, it can cause a lot of challenges. I will try to explain some of the common issues which make the entire process unsafe.

The first thing which people face is the lack of penetration which can lead to safety risks. A lot of amateurs only join the bases at the surface, this will not help the frame at all when it is put under stress. The second issue is the lack of control while welding. This includes not only the welding technique but also the support the frame is on. This is one of the reasons why the best welds on a frame happen in controlled environments in factories.

On top of this, a poor weld can severely compromise the safety of a frame. I know I have stated this multiple times in the article but welded frames are 80% more likely to fail at the welding points as compared to a solely constructed frame.

WILL WELDING DAMAGE VEHICLES ELECTRONICS

The answer to this question isn’t straightforward. If the welder doesn’t take the necessary precautions while doing the weld, it is a big possibility that your electronics may get damaged. It is especially important to consult the manual or the manufacturer of your car before starting a weld in the case of newer models of cars. Over the last couple of decades, the electronics inside a car have become increasingly complex and integrated with the system that’s why consultation becomes important.

Once you have consulted the manufacturer there are a few things which you should keep in mind. First, make sure that your negative battery terminal is disconnected from the vehicle before you open the electrical circuits to your car battery. This will help you reduce the risk of damage due to overvoltage.

Try to place your welding ground clamp close to your welding arc. This will ensure that the electrical path is as short as possible between your arc and the ground.

HOW MUCH DOES IT COST TO FIX A CRACKED SUBFRAME

The costs related to fixing a cracked frame can vary largely depending on the extent of the damage and the area which needs to be fixed. For example, a hairline fracture will be less costly when compared to an extensive crack. On the other hand, cracks that have occurred because of rust might be even more expensive because of the added restoration time and labor attached to it, these repair costs can run to about the 3,000$ mark. Sometimes the overall repair costs related to welding a truck frame can reach about 10,000$.

IS IT WORTH FIXING THE FRAME

There are multiple factors that you should consider when tackling this question. One of the factors is the end result, most of the time when you get your vehicle’s frame fixed the end result is not the same as the original. This is both in terms of the structural integrity and the safety of your vehicle. You should only choose a professional with years of experience when it comes to fixing your car’s frame.

The second factor being that of the cost. As I said earlier the overall cost of getting your frame fixed can run into thousands of dollars. Therefore, you should only go for the repair option if your vehicle is new enough to maintain value greater than this.

The third factor can be the legality of your vehicle. You might get your frame fixed within a reasonable budget and good enough quality but what if your local laws don’t allow the vehicle to be road legal. There are a lot of factors to consider when it comes to getting your frame fixed.

ARE THERE OTHER WAYS TO FIX THE FRAME

There are a few ways of repairing vehicle frames other than welding but of course, there is no magic one size fits approach. The first thing you should consider is that usually when a frame of a vehicle has been damaged, the car or the truck might be unsalvageable. This does not mean that there is no way it cannot be repaired but the practical costs related to the repair might become astronomical and the result might not even be good.

Some people recommend that other than welding a bracing system might be a good alternative to deal with cracks in the truck frame. This can be done by securing the compromised areas using a bolt and metal brace. But similar problems are associated with this method, namely, it might result in dubious reinforcement. All in all, this method also should be overlooked by a trained professional.

FREQUENTLY ASKED QUESTIONS:

This is one of those topics which you shouldn’t have any doubts while making a decision. whether you are deciding to weld a car frame or get it fixed by some professional, it can be a huge decision both economically and in terms of safety. So you shouldn’t have any doubts regarding the subject. I will try to address some of the most common queries which I hope help you out.

It depends on the level and intensity of the rust affecting your frame. A little bit of rust can be dealt with by a professional welder. But when the rust starts making holes and cracks or start affecting the structure, it might not be possible to get it fixed, and even if it does the end result might not be safe enough.

The question here is not ‘if’ you can, it is ‘should’ you drive a truck with a cracked frame? The answer of course is a no. As I have stated before, the frame might be the most important part of the car and if it gets cracked it compromises not only your safety but other vehicles around you as well.

If your battery isn’t disconnected it increases the chances of your car electronics being affected during the weld. When the battery is disconnected the loop is broken and it will prevent overvoltage damage.

CONCLUSION

To sum it all up, you should be very careful while selecting the person who will work on your car or truck frame as a small mistake can affect your vehicle’s safety. But before you do that be sure to measure the pros and cons of getting your frame repaired, including the cost and safety factor. Also, be aware of the fact that a lot of times people are not able to tell if their frame has been compromised so you should know the different ways you can check for defects. When you decide to get your frame welded or fixed, consult with an attorney about the legality in your jurisdiction.

More welding-related reading: