Have you heard from someone about issues related to welding zinc plated and galvanized metals? Even if you haven’t, the process is not the same as welding any normal metal. There are a few things that you should keep in mind if you are going to attempt welding on zinc plated metals. A lot of these tips and tricks are safety-related not just about the quality of the weld, so it is important for you to know all of these factors.

Before we get into each and every subtopic, there are a few things that you should keep in mind. There is a very minute but important distinction between galvanized steel and zinc-coated steel. You need to be extra careful when it comes to welding galvanized steel as it can have long-lasting health issues. This is why you should be aware of zinc poisoning signs so you can accurately determine if you are suffering from them or not.

A while back I did a DIY Video where I used galvanized steel thinking to myself how bad can this stuff be to my health. I was wrong, and believe me, I will never do it again. So I decided to do some research on the topic.

Let us get right into it.

THE DIFFERENCE BETWEEN GALVANIZED AND ZINC PLATED STEELS

Contents

Very few people know the difference between the two, although they are largely the same procedures, the end products can be drastically different.

Galvanization helps the steel or iron against rusting by applying a protective zinc coating on the metal. A lot of people consider that hot-dip galvanization is the only true form of galvanization, the reason for this will be clear in the following paragraph.

Zinc plating is also known as electro-galvanization, the reason for this is the method through which the plating occurs. The zinc plating occurs through an electric current.

From afar these methods might look pretty much the same but the reality is pretty different. While both methods involve coating the metal with zinc, the main difference occurs in the thickness of the coating. Zinc plating has a thin layer of zinc which only offers a fraction of rust protection. The main reason why people opt for zin plating is the cheaper cost and ease of welding.

Hot-dip galvanization on the other hand offers a thicker coating of zinc. The difference in the thickness between the two methods can be quite significant. The minimum coating thickness for zinc plating is 0.005mm and can go up to 0.25mm, on the other hand, the minimum thickness of the galvanized coating is 0.45mm and can be beyond 0.1mm.

A lot of sellers or manufacturers sell zin coated metals under the tag of galvanized products, so you should be aware of that.

HOW DO THE DIFFERENT PROCESSES WORK?

Hot-dip galvanization takes place by dipping the metal in a hot 450C bath of molten liquid zinc. Because of this the steel and the zinc particles bond with each other due to the high temperature. Zinc plating works by submerging the metal in a cold chemical solution of zinc and the coating takes place by passing an electric current.

CAN ALL METALS BE GALVANISED?

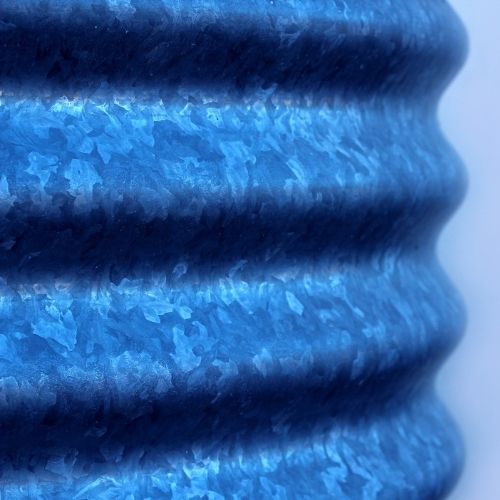

Both the methods of galvanization can be applied to any steel product no matter the size, ranging from small bolts to entire building beams. One way of recognizing hot dipped galvanized products is to check the look and feel of the metal. The hot-dipped method leaves a dull grey color and a rough feel while zinc coating is usually shiny and smooth.

GALVANIZED STEEL MELTING POINT

There are a few interesting things to note here. There will be three melting points you will be dealing with. The first is the melting point of pure zinc on the top, which is around 420 C. Steel on the other hand can vary a lot depending on the grade of steel being used, it can move between 1425 to 1540 C. the iron-zinc alloy layer between the base metal substrate and the pure zinc on top is somewhere around 600C, below the melting point of steel.

The interesting thing is that zinc turns into a gas at a pretty low temperature which can cause issues during welding. Long term usage of galvanized steel is not recommended at a temperature above 200 C consistently.

IS GALVANIZED STEEL TOXIC?

One thing to note is that zinc by itself is not poisonous. There is zinc present in a lot of food items and they are probably present in your multivitamins. Galvanized steel also by itself is not toxic, it is used in a lot of applications and if you are touching it, bending it, or scraping it then you should be fine. Of course, it goes without saying that you should not try to eat any of this, which will probably cause you some trouble.

The problem arises when you start welding it. Zinc turns to vapors at a relatively lower temperature and when you are welding on galvanized steel, it can cause toxic fumes which can be very harmful to your health. This is also another reason why you shouldn’t use galvanized steel utensils while cooking. Some people also recommend not to store acidic foods in galvanized steel containers.

HOW IS WELDING GALVANIZED STEEL DIFFERENT FROM WELDING REGULAR STEEL?

It is not that the technique in itself is very different when it comes to the actual welding. The difference arises when it comes to the safety measures and precautions you will have to take when welding galvanized steel. The reason for this is pretty straightforward, the zinc coating has a lower vaporization temperature when compared to the melting temperature of steel. As the welding process involved melting of the base metal, it is obvious that the zinc will also end up vaporizing.

This zinc vapor joins the existing smoke and fumes, here the zinc forms zinc oxide after reacting with the oxygen in the air. Interestingly this zinc oxide is not what is the most dangerous factor of welding, it will only cause some temporary issues, and zinc oxide on its own is not toxic.

Most of the zinc being used for galvanization contains some amounts of lead in their composition, usually less than 9%. When this lead gets vaporized and it forms lead oxide with oxygen, it can lead (no pun intended) to some nasty results. It is extremely toxic and can lead to problems such as anemia, kidney dysfunction, or even cancer.

HOW TO WELD GALVANIZED STEEL PROPERLY?

As I stated earlier, the actual welding process is not that different from welding uncoated steel but it is the preparation aspect which is different.

THE PREPARATION

You should start by getting rid of the zinc coating around the area you are going to weld. This applies to any of the welding technique you are going to use. You can also reduce the amount of spatter that is produced if you remove the zinc layer. The layer can be removed through the simple grinding method and is pretty effective, although don’t expect to remove all the zinc from the weld area.

It is important that you grind until you get to the clean steel under the Zinc or Galvanized steel. Especially when dealing with hot-dipped steel. At first, it may seem like you got all of that nasty stuff away, on closer inspection you probably will see it is pretty thick and takes quite some time to grind off.

If you are dealing with hot-dipped pipes, as a hobbyist, I would not even bother. You can not clean the pipe from the inside and the gases will come through a regular respirator. When I made the Alaskan Sawmill (blueprints here). I experienced that and I must say, it is not worth it. You are better off buying clean metal than working with galvanized stuff from the scrapyard.

THE WELD

After you have grinded away the zinc layer you can go ahead with the weld. You can use a standard arc welding technique which you would use on uncoated steel metal. Put the pieces of metal you are going to place in the desired position using clamps and make sure you are not welding on top of a combustible surface.

I would recommend that you use the standard flux-core welding or stick welding, because of its versatile nature and the fact that they can deal with contaminants better. I would recommend that you take extra care while grinding off the zinc if you are going to use TIG or MIG method. With stick welding, you can try using a deeper penetration electrode to go through a thick zinc coating, although it is not always necessary. Make sure you do it outside though if you do not have a great ventilation system in place.

SAFETY HAZARDS

Try to avoid the fumes as much as you can. This is the perfect opportunity for you to invest in a good welding mask or a respirator. One tip to follow is to only remove your mask once you have left the room you were welding in. You can also use fume extractors which will help clear out the room faster. Make sure you are welding in a well-ventilated room in this case.

HOW TO PROTECT GALVANIZED STEEL FROM CORRODING AFTER WELDING?

It is quite obvious that the zinc layer will get vaporized during the welding and this can leave the welded metal prone to corrosion after the process is over. If you are looking to regain the anti-rust property of the welded area you might have to paint the welded area using paints containing zinc dust. You can also go for re-galvanization of the welded metal but this is usually avoided because of the higher costs associated with it.

ZINC POISONING SIGNS

I am going to strictly talk about the symptoms you can experience through exposure to fumes because of welding galvanized steel.

Some of the most common effects that people encounter are zinc chills, zinc shakes, or galvanize poisoning. You can start feeling the effects a few hours after being exposed, usually, they come during the night. Some of the symptoms are fever (usually around 102F), a sweet taste in the mount, nausea, fatigue, chills, vomiting. These symptoms usually subside within a day or two but you shouldn’t keep exposing yourself to the fumes as they can lead to long-term damage as well.

Again, luckily I did not get a fever from welding the galvanized pipes, but I did get a sweet taste in my mouth. It also felt a bit numbing. I think the respirator saved me in this particular case from more serious symptoms.

FREQUENTLY ASKED QUESTION

It is pretty common for people to have a lot of questions related to this topic. Considering the fact that this topic can have serious health consequences it is important for anyone to get rid of any doubts they have regarding the method. I will try to address some of the most common questions related to this topic. Hope it helps.

Contrary to popular belief, zinc does rust but not in the same way as steel. Zinc works to protect steel in two ways, by protecting the steel from moisture and the environment. Without which steel will not rust. What it means is that zinc is more reactive than steel so even if there is a small scratch on the surface zinc will oxidize first. This means that steel will only start corroding once the surrounding zinc has been consumed. The speed at which zinc corrodes is much lower, almost by a factor of 10, when compared to steel.

Both the metals do a pretty good job of protecting the materials against rust. A lot of people prefer to use stainless steel as it provides better rust resistance when compared to galvanized steel, although I am not completely sure about this.

This is a common misconception which I thought needed to be addressed. There is no proof that drinking milk can actually help with the effects of inhaling fumes, but a lot of people claims that it helps with the immediate feeling of nausea.

CONCLUSION

To sum it all up, galvanized steel usually means that the steel has been dipped in liquid zinc which gives it rust-resistant properties. But this also adds some complications which people face during welding the material like toxic fumes which can cause severe long-term health issues. This is why you should make sure to grind away the zinc coating near the area of the weld and to wear a good mask while welding. The first signs of zinc poisoning are sweetness in the mouth, nausea, chills, and fever to name a few. Be safe and keep practicing!

Recommend you to read this as well.