MIG welder is a must at most welding shops. It is one of the most famous methods today as it also can be controlled by robots. It is simple enough that it also can be operated at home by the enthusiast. You only need a few tools and you already can make amazing welds with a little bit of practice. However, the MIG welding evolution itself started over sixty years ago. That is when people first started learning the use of consumable wire electrodes in producing an electric arc, to melt and join separate pieces of metals together.

MIG welders are referred to as one of the easiest to operate and use in creating crisp, precise and strong welds. Today, MIG welding is multipurpose, it can be used for a number of different projects involving various metals, although it is mostly used for hobby welding, equipment maintenance, auto bodywork, and manufacturing.

Thanks to MIG welding, the modern industry of welding is where it is now. Without it, a lot of products that we are using today couldn’t exist at such a low cost. It’s just right that we learn and understand how this amazing invention came to life, as well as how it has evolved and has been refined through the years and has become the welding process that a lot of people love today.

When Was MIG Welding Invented?

Contents

You might be wondering what does a MIG stands for in welding. Well, MIG actually stands for Metal Inert Gas. This is a welding process where an electric arc is created between a base metal and wire electrode (filler wire) that heats the metal, thus causing them to melt and eventually join.

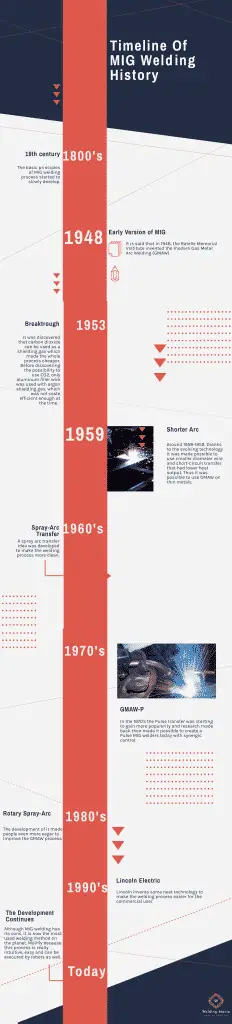

The principles of MIG welding actually started to establish in the 19th century, with the discovery of electric arc by Humphry Davy in 1800. At first, carbon electrodes were utilized, yet in the late 1800s, the metal electrodes had been developed by C.L. Coffin and N.G. Slavianoff.

Some forerunners to modern MIG welding were actually invented in the early 20th century. However, these didn’t rely on inert gas to protect the weld and they were not ideal for use because of some shortcomings in the technology.

It was in 1948 that Batelle Memorial Institute invented the modern gas metal arc welding or GMAW. This is considered to be the early version of MIG welding, which used a smaller diameter wire as an electrode, compared to the ones used before. Thanks to this it was possible to start using this technique on thinner materials like we do today.

MIG Welding History Throughout The 20th Century

Mid-20th Century

Since the shielding gas, which the MIG welding depends on was expensive for the steels, the process was too costly and the welders were only limited to welding materials such as aluminum.

This changed in 1953 when Lyubavshkii and Novosiloov succeeded when they made use of carbon dioxide as a gas shield after their numerous failed attempts in 1924. Their work did not just make wire feed welding more inexpensive, but it also gave an opportunity for welders to work with regular steel in various thicknesses, as it helps to penetrate more deeply.

In 1958, a variation of GMAW that used a shorter arc was released. The use of electrode wire with smaller diameter enabled short-circuit transfer that utilized lower heat levels. This became so popular because of its ease of use and versatility. Now it was possible to weld thin materials with MIG effectively.

The 1960s

In this decade, people saw the arrival of the spray-arc transfer, a variation of GMAW. By injecting small quantities of oxygen in the inert gases, very few splatters would be produced.

With the development of pulsed spray-arc variation or GMAW-P, the welding has become even more advanced. Through the use of pulsed current, which switches from high to low currents at quick speeds, welders help to reduce the quantity of splatter produced while welding. This was a huge step towards the future of MIG welding. Thanks to this it is easier to make more clean and stronger welds that can stand the pressure.

The 1970s

Further developments of GMAW in the 1970s depend on the advancement of power source technology. Discoveries in this particular field allowed for the GMAW-P and GMAW processes to be improved and refined. Thyristors that are invented in 1950 were started to be used in various welders designed for commercial use.

These were able to stabilize the voltages and were very convenient to commercial users. All thanks to their large number of uses and small sizes, even though they’re mostly used for light dimmers.

The 1980s

The rotary spray arc came about in the early 80s. This caused the start of some more inventions, which aimed to achieve high rates of deposition with no rotary spray arc, just like the TIME process and a patent developed in 1984. This used a gas combination that may allow for both rotary spray arc and normal spray arc.

All of these advancements persistently inspired others in improving the MIG welding process further.

The 1990s

In this decade, Lincoln Electric developed the first-ever sold commercial unit for the new MIG welding process that’s now used by nearly each main welding contractor in the whole world. The process uses surface tension transfer that offers much greater control to the welders, and minimizes splatter, thus allowing for high-quality welds.

A waveform generator helps to control the power through the surface tension transfer technology makes the current independent from the wire feed speed. This just means that the electric current might be controlled without the need to add more wire.

The surface tension transfer technology has changed the MIG welding for the better and brought us to the MIG welding that we have today.

MIG Welding Today

The 21st century is the real golden age of MIG welding. And even though GMAW is not suitable for welding outdoors, in space or underwater, its use is still extensive. MIG welding has been put in the hands of robots who use the process in the mass production of different products and goods.

This is all thanks to the improvements through the decades, as well as the hard work of numerous scientists and inventors who kept on revolutionizing and innovating until the GMAW became what it is today.

Nowadays, the advancements are made by different companies who’ve been relying on modern technology to study the arcs’ characteristic. All of these innovations may allow MIG to be used more often in some other, least developed counties as well.

With the modern-day scientists and inventors making much newer methods of welding like friction welding or laser welding, there are high anticipations that the future is really bright for MIG welding. We will surely see more and more innovations that will revolutionize the industry further, as well as build on MIG’s rich history.

I also designed a nice timeline about the history of MIG welding. To zoom in, click on the picture.

Also, feel free to share it!